Overview

The biopolymers and biocomposites team consists of researchers with diverse backgrounds, including materials and polymer science, mechanical engineering, chemistry and biotechnology. The team works on developing products and technologies, utilizing agricultural residue and co-products to solve environmental, health and social issues. Agricultural byproducts and coproducts are converted into value added bioproducts to replace synthetic polymer based products. Examples include biodegradable and inexpensive packaging materials for food and non-food products, biodegradable printed circuit boards, low-cost fiber-based sapling pots and trays, light-weight highly-insulating false ceilings, etc. All products are developed using agricultural residue such as rice straw, wheat straw, sugarcane bagasse, coir fibers, banana fibers and coproducts such as oil meals, chitosan and alginate. Agricultural byproducts and coproducts are also used to produce enzymes, biofuels and synthesized nanoparticles. The team is also working on utilizing byproducts of silk processing, particularly sericin, for value added applications. These efforts contribute towards a biobased economy where exploitation of natural resources is minimized and the concept of “Waste to Wealth” is practiced. Bioproducts developed by the team require simple technology and are highly cost-effective, facilitating easy adoption by industries and in rural areas. Continued research at the lab has led to the development of patented processes for the production of biodegradable packaging materials and to the establishment of a start-up company, “Agringenium Innovations Private Limited”. The start-up has received grants from state and national funding agencies. The team has several collaborations with researchers in universities from China, France, Italy, Portugal, Thailand and the United States.

Overview of the research and product development in the biopolymers and biocomposites laboratory

Overview of the research and product development in the biopolymers and biocomposites laboratory

Books/ Book chapters from the Biocomposites team

Reap all you Sow

Agriculture is a natural resource and labor intensive process. It is not apparent that most agricultural crops generate residue or biomass that is considerably larger than the intended produce. For instance, the amount of leaf, stalks and husks left from corn and sugarcane are much higher than the corn or sugar generated. It is unfortunate that most of this residue remain unused or used for low value applications such as fuel for burning. This not only creates pollution but also disposes an otherwise valuable resource. Residue from agricultural crops are being converted into various value added bioproducts in our laboratory. These products have been developed without the use of chemicals and are 100% biodegradable. They find application in agriculture, automotive, construction, electronics, and food industries. Prototypes of these products are available in the lab and the technology to manufacture these products has been patented.

Value-Addition to Biofuel Crops

Oil seed crops are being aggressively promoted as environmentally friendly and sustainable source for biofuels, specifically biodiesel. Neem, castor, pongamia and jathropa are commonly used for biodiesel. Conversion of oil seeds into biodiesel generates anywhere from 25% to 50% of the seed as meal or cake which is mainly used as animal feed or fertilizer fetching less than Rs. 30 per kilogram. Oil cakes contain large amounts (20-50%) of proteins that have unique properties and are suitable for developing several other products. Converting oil cakes into bioproducts or utilizing proteins in the meal for high value applications will add considerable high value to the meal and, hence, reduce the cost of biodiesel. Oil cakes/proteins in oil cakes are converted into films, fibers, disposable cups, nano and micro particles, and 2D and 3D scaffolds for multiple applications. Proteins from some of the oil seeds have been identified to have anticancer and antimicrobial properties, and are specifically studied for medical applications, including treating cancer.

Protein based biodegradable cups Scaffolds for tissue engineering from plant proteins

Replacing Plastic-based Packaging Materials

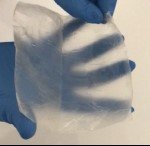

Indiscriminate use and disposable of synthetic polymer based materials is a major cause of pollution. Ubiquitous use of plastic-based packaging for food and non-food applications is the most prominent contributor to municipal solid waste and related pollution. Current alternatives to plastic based packaging, including biodegradable plastics, are either expensive or need specific conditions for degradation. Researchers at the biopolymers and biocomposites lab attempt to develop 100% biodegradable packaging materials using agricultural residue without using any chemicals or synthetic polymers. Residue such as straw and bagasse, in combination with the oil meals, are being used to develop different types of packaging material. Unlike the common approach of pulping or chemical treatments, the residue areused in their native form ensuring that their unique properties are retained and the cost of production is minimized. Prototypes of rectangular and circular containers, transparent and flexible films, and cups and bags for food and non-food packaging are available in the lab.

Completely biodegradable plates (left), cups (center) and packaging films (right) developed using biofibers and/or biopolymers

Sustainable Products/Technologies for Environmental Remediation

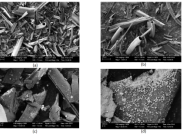

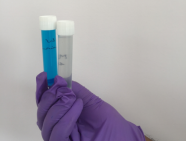

Access to heavy metaland chemical-free water is a constraint in most rural areas. Similarly, water pollution due to discharge from industries and other human activities is quiet extensive. Processes such as textile finishing and coloration, and paper production generate considerable amount of toxic/non-degradable chemicals. Sustainable technologies and products are necessary to reduce or remove contaminants in water. Agricultural residue and coproducts offer an ideal opportunity to develop biobased sorbents for metals, dyes and other pollutants. Researchers at the lab have developed green chemicals, fibers, biobased carbons and other sorbents for waste water treatment. Protein-based sizing agents for textile finishing, dyes and pigments from natural sources and unique adhesives and gums from plants have been identified and developed for environmental applications.

Biosorbents for waste water treatment. Biocarbon from milkweed (left), dye removal using proteins (center), properties of milkweed biocarbon (right)

Biomaterials for Medical Applications

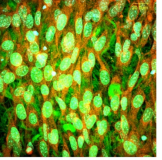

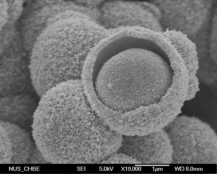

Low-cost and affordable medical devices and products are necessary to address increasing medical costs and treat challenging and emerging diseases. Biopolymers are desired for medical applications since they have better biocompatibility with the body and do not release toxic substances upon degradation. Starch, cellulose, chitosan, collagen and silk are some of the biopolymers used for in vitro and in vivo medical applications. However, processing these biopolymers or achieving products with desired properties is a challenge or has considerable constraints. Proteins are preferred to synthetic polymers or carbohydrates since they have better biocompatibility with the body. Collagen and silk, used for a few medical applications, cannot be made into most forms of biomaterials due to toxicity issues. Researchers at the lab have identified plant and oil meal proteins that can be processed into films, fibers, nano and micro particles, and 2D and 3D scaffolds for tissue engineering, controlled drug release and other applications. Plant/oil cake derived proteins have shown suitability for in vitro and in vivo applications.

Soyprotein scaffold for tissue engineering (left), hollow protein nanoparticles for drug delivery (center) and 3D scaffold from plant proteins for tissue engineering (right). Nanoparticle image from https://www.nanoshel.com/core-shell-nanoparticles/

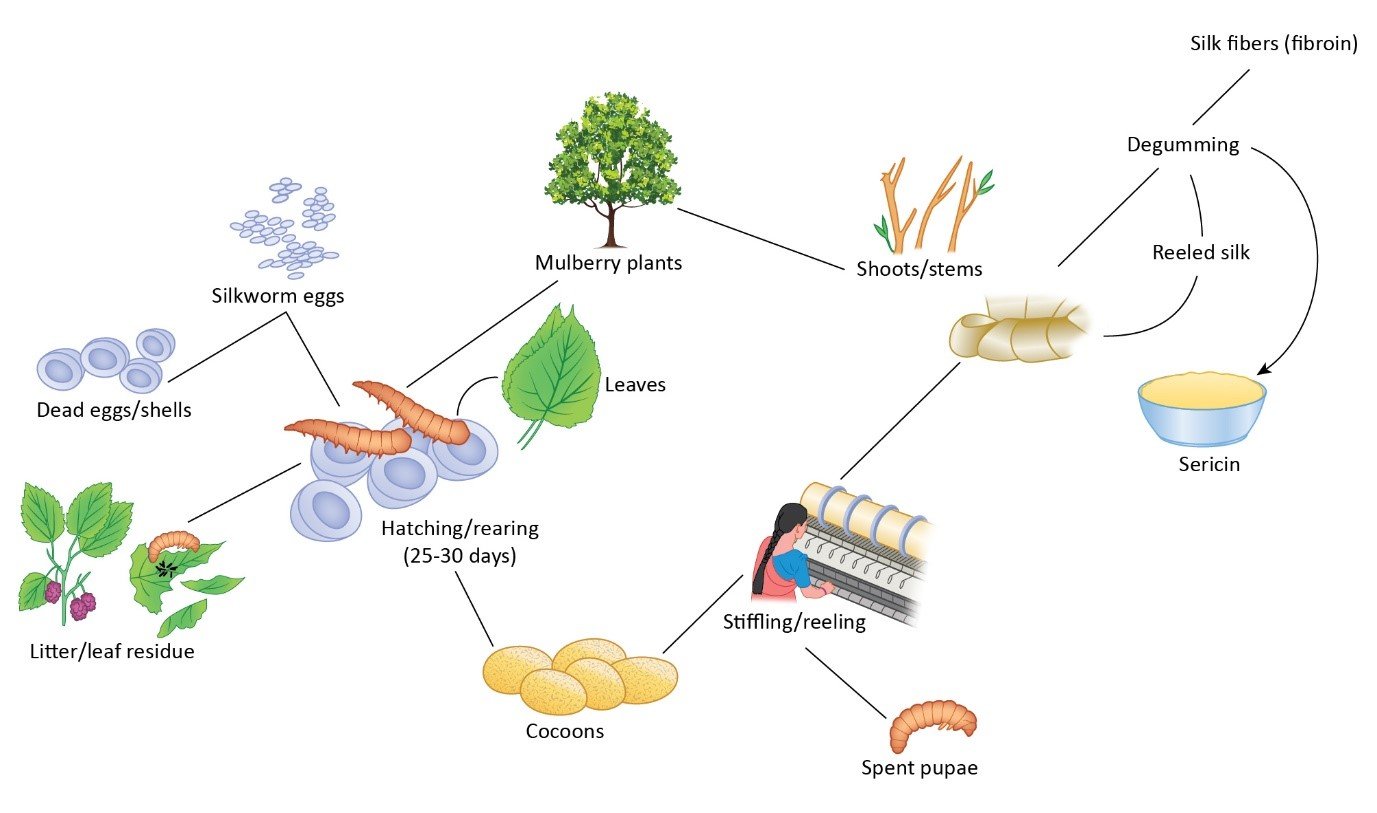

Value Addition to Byproducts of Silk Processing

Silk is one of the prominent industries and mulberry cultivation is one of the most important agricultural activity in Karnataka. Processing of silk generates considerable byproducts and coproducts that have limited applications and are generally disposed of as waste. Researchers at the lab utilize these byproducts and coproducts for food, feed, energy, medical, biotechnology and other applications. Stems left over after harvesting the mulberry plants have been converted into biocomposites. Spent pupae have been used to extract oil which, later, has been converted into biodiesel. Proteins in silkworm pupae and sericin have been used for various applications. Similarly, the use of silkworm litter is being explored for potential applications. These efforts are aimed at increasing value from silk processing and ensuring that sericulture processes are sustainable and economically viable.

- Guna, Vijaykumar, Manikandan Ilangovan, H. R. Vighnesh, B. R. Sreehari, S. Abhijith, H. E. Sachin, C. B. Mohan, and Narendra Reddy. “Engineering sustainable waste wool biocomposites with high flame resistance and noise insulation for green building and automotive applications.” Journal of Natural Fibers, 18, No. 11, (2021): 1871-1881. IF : 5.3

- Rai, Aayush, Seemesh Bhaskar, Narendra Reddy, and Sai Sathish Ramamurthy. “Cellphone-Aided Attomolar Zinc Ion Detection Using Silkworm Protein-Based Nanointerface Engineering in a Plasmon-Coupled Dequenched Emission Platform.” ACS Sustainable Chemistry& Engineering, (2021). IF : 8.3

- Reddy, Roopa, Qiuran Jiang, PornanongAramwit, and Narendra Reddy. “Litter to Leaf: The Unexplored Potential of Silk Byproducts.” Trends in Biotechnology 39, No. 7 (2021): 706-718.IF :19.3

- Battampara, Prajwal, T. Nimisha Sathish, Roopa Reddy, Vijaykumar Guna, G. S. Nagananda, Narendra Reddy, B. S. Ramesha, et al. “Properties of chitin and chitosan extracted from silkworm pupae and egg shells.” International Journal of Biological Macromolecules, 161 (2020): 1296-1304. IF : 5.6

- Ilangovan, Manikandan, Vijaykumar Guna, B. Prajwal, Qiuran Jiang, and Narendra Reddy. “Extraction and characterisation of natural cellulose fibers from Kigeliaafricana.” Carbohydrate polymers, 236 (2020): 115996. IF : 7.5

- Electrochemical approach for recovery of silk sericin from degumming waste water DST.

- Green Valorisation of Sheep Wool Waste towards Biocomposites and Bioactive Building Materials. CEFIPRA (Indo-French Collaborative Project)

- Converting agricultural residues into value added bioproducts, Atal New India Challenge (ANIC), NITI Aayog, GoI.

- Utilization and Commercialization of by-products of sericulture industry through value addition, KSSRDI, Department of Sericulture, Government of Karnataka.

- Developing high value polymeric materials for the food, fibre, biofuel composites, medical and automotive industries using indigenous renewable resources. DBT, GoI.

- PornanongAramwit, Chulalongkorn University, Thailand

- Chunyan Hu, Donghua University, China

- Anand Sanadi, University of Copenhagen, Denmark

- Benjamin Saulnier, University of Sud, France

- Quiran Jiang, Donghua University, China

- Yi Zhao, Donghua University, China

- Helan Xu, Jiangnan University, Wuxi, China

- Francois Touchaleaume, University of Montpellier, France

- Antonio Greco, University of Salento, Italy

- Sergei Tverdokhlebov, Tomsk Polytechnic University, Russia

Narendra Reddy

Narendra Reddy is one of the prominent researchers in the field of biopolymeric materials. He obtained his doctoral degree from the University of Nebraska-Lincoln in USA in the year 2006. He has published about 175 research papers in high impact journals, five books and 8 book chapters. He also holds an US patent. His work has been cited more than 8000 times and he has a high H Index (45) and I 10 index (116). His work has been reported by CNN, Discovery, Nature, American Chemical Society and other major news agencies. He was a recipient of the prestigious Ramalingaswami Fellowship from the Department of Biotechnology, Government of India. He has received funds from his research from DST, DBT and CEFIPRA (India-France joint funding). He is also the founder of a start-up “Agringenium Innovations Private Limited” which has been selected by Niti Aayog for funding through Atal New India Challenge (ANIC).

Email Id: narendra.r@ciirc.jyothyit.ac.in

Vijaykumar Guna

Vijaykumar Guna completed his PhD from Visvesvaraya Technological University in 2021. His area of work is in developing biobased composites from agricultural residues. He is a mechanical engineer by training and obtained his bachelor’s degree from Bangalore University in 2012. Subsequently, he graduated with his M. Tech in Energy Engineering from Jain University, His research work has resulted in more than 15 publications in high impact journals. His work has been extensively cited and reported in various scientific journals. He is also assisting in commercializing the biobased composites for construction, automotive and other applications.

Email: vijay.kg@ciirc.jyothyit.ac.in

Prajwal

Prajwal holds a Bachelor’s degree in Mechanical Engineering and works on multidisciplinary researches. He has worked on multiple research topics including utilizing agricultural residues for energy applications, extraction and characterization of carbohydrates from animal and plant wastes and on utilizing silk industry byproducts for value added applications. He has also been trained to operate sophisticated instruments.

Shubha

Shubha is a chemist by training and has Master of Science in Chemistry and bachelor’s degree from Mangalore University. She is working on developing metallic nanoparticles using plant extracts. In another research area, she is developing films using proteins from oil seed cakes and silk sericin. She has worked in quality control for chemical industry and has knowledge of several high-performance instruments.