Overview

Most of the engineering applications involve heat and mass transfer. The rate at which heat transfer takes place would eventually determine the performance of the device/machine. Efficient heat transfer would ensure hazzle-free functioning of the device and also increases its life. The research team at the lab is currently working on design and development of heat transfer devices and materials such as cost effective indigenous thermal interface material, design of novel heat sinks for reduced junction temperature in LED lighting systems, natural convection in rotating enclosures and design, and development of multiloop pulsating heat pipe for heat transport. The team is also focused on the areas additive manufacturing and rapid prototyping.

Thermal Interface Materials (TIM)

Heat transfer in LED lighting solutions is generally enabled by employing thermal tapes to join the components. However, these tapes are very expensive. In this age of high competition, a thermo-adhesive material would be best suited to minimize this cost. The research team at the lab is developing novel materials for this application by using MWCN based thermal pastes. Experimental results have demonstrated improved heat transfer characteristics. Further study is on with respect to their adhesive properties.

Heat Sinks

All heat sinks are provided with fins to dissipate heat from the heat source. With limitations on their shape, size and operating environment, fins may not be efficient enough to remove heat generated. The lab is currently developing and testing novel designs for heat sinks used in LED lighting applications that seek to improve heat transfer, given existing constraints.

Numerical Simulations (CFD)

- The natural convection flow phenomena inside an enclosed space, is an interesting example of very complex fluid systems that may yield to analytical, empirical and numerical solutions. Natural convection in enclosures is always created by the complex interaction between the fluid and heat with all the walls. Internal interactions will cause a diversity of flows that can appear inside the enclosures. In many engineering applications and naturally occurring processes, natural convection plays an important role as a dominating mechanism. Natural convection in a differentially heated enclosed space is often encountered in various engineering applications such as solar energy collection, cooling of microelectronic equipments, growing of single crystal from fluid phase, energy storage devices, furnace design and many others. A CFD studies were carried out to investigate the effect of Rayleigh number with rotation on the flow and heat transfer characteristics in a differentially heated enclosure. An in-house Code was developed based on FVM to discretize governing equations. Upwind difference scheme for convective terms and fully implicit scheme for transient terms were used. The SIMPLE algorithm was employed to couple pressure and velocities on staggered grid arrangement.

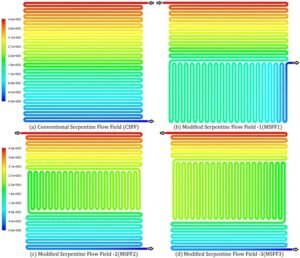

- To reveal the hydrodynamics of the different flow field designs for Redox flow batteries, CFD analysis were conducted using FVM code with 2nd order upwind differencing method for treating convective terms. The SIMPLE algorithm is used to couple the pressure and velocities on staggered grid arrangement with pressure being descriterised using 2nd order scheme. The porous substrate is modeled by the addition of source term to the momentum equation. This comprises of two components, a viscous loss term and an inertial loss term were solved with relevant boundary conditions are solved using in-house developed code to ensure the convergence. Modified serpentine flow field – 2 (MSFF2) design provided least pressure drop across the channel and maximum velocity penetration across the porous substrate when compared to the other designs. This increases its wetting ability that is very important in terms of mass transfer over potential for electrochemical reaction happening in the porous substrate to achieve effective electrochemical cell performance.

- Pulsating heat pipes (PHPs) are passive heat transfer devices where the heat transfer is much higher as compared to the general heat transfer devices such as metal fins. The main reason for this is the two phase phenomenon happening inside PHPs with the oscillatory motion of the bubbles. It can be used in various applications, space satellites, laptops or any other place where you want heat transfer to be very high in a small temperature drop. The CFD studies were carried to model the two phase flow using a single fluid formulation based on VOF method were used for modelling the slug flow in capillaries. The hydrodynamics were described by the equations for the conservation of mass, momentum and energy together with an additional advection equation to determine the gas-liquid interface. The performance parameters such as temperature difference between evaporator and condenser, thermal resistance evaluated. The obtained simulation results are compared with the experimental trials under the same condition.

Experimental studies

- Pulsating heat pipes (PHPs) are passive heat transfer devices where the heat transfer is much higher as compared to the general heat transfer devices such as metal fins. The main reason for this is the two phase phenomenon happening inside PHPs with the oscillatory motion of the bubbles. It can be used in various applications, space satellites, laptops etc where high heat transfer is required with small drop in small temperature. Experimental studies on the development of flat plate pulsating heat pipe (FPPHP) for space application is in progress

Tribology

Tribology is the science and technology of relative motion between interacting surfaces. The domain of tribology includes the study of friction, lubrication and wear. Relative motion between two mating surfaces in machine members requires special attention to friction. Improper lubrication results in loss of precision in manufacturing and, hence, loss of productivity; this, further, leads to serious economic losses to the industry. Lubrication minimizes the stick-slip phenomena between the interacting surfaces. As machines consist of a number of moving parts, there is a huge demand for lubricants to meet the needs of a number of industrial applications. Recognizing this high-felt demand, the Centre is actively involved in the design and characterization of specific industrial additive-based lubricants that can enhance the life of machine members.

Polymer Tribology

Polymers, by virtue of their ease of processing and low cost of production, have become the most sought-after materials for industrial applications, replacing traditional metals and materials. Their scope in industrial and structural applications has been ever increasing. In this context, the Centre is involved in developing polymer composites materials for machine parts. These composites have a polymer matrix filled with varying volume percentage of reinforcements to improve the mechanical and tribological properties of the composites. Such composites have the potential to replace a monolithic material.

Lubricant Tribology

Linear motion guideways are one of the most critical parts of machine tools. The main factor affecting the performance of guideways is friction. In sliding contact guideways, the relative motion between the elements is sliding, thus giving rise to sliding friction. Reduction of friction, either through improved design, or through the use of more suitable contacting materials, or again through the application of better lubricating substances, is thus an extremely important problem of modern technology.

Lubricants and coolants, being the mainstay of the automotive and machine tool industry for reducing friction and wear, become important from both the operational and manufacturing points of view. Generally, the smoothness of movement is improved by reducing friction. Though frictional force is reduced by the application of lubricant, it is also important to keep the frictional force steady. Unsteady or variation in frictional force leads to jerky motion or stick slip in machine tool slideways. Thus, stick slip, in tribology, is a cyclic fluctuation in the magnitudes of friction force and relative velocity between two elements in sliding contact, usually associated with a decrease of the coefficient of friction with onset of sliding or with increase of sliding velocity. In most practical sliding systems, these fluctuations of the sliding velocity are considered a serious nuisance, and measures are taken to eliminate or reduce the amplitude of these fluctuations.

The requirements of linear guideways and industrial lubricants are rising, especially for machine tools which have to meet various demands such as high positioning exactness, good compatibility with coolants, stick slip free with low coefficient of friction over a wide speed range and good demulsifying behaviour on metallic slideways. These requirements can be achieved by employing different slideway materials and design of lubricants by the addition of different additives like Boron Nitride, etc. The tribological efficiency of these lubricants with regard to linear guideways is tested using a reciprocating tribometer or a four ball tester. Research at the lab investigates of tribological efficiency of lubricant (oils and greases) or coolant governed by a number of parameters. These include the sliding speed of the mating members, physical and chemical properties of the lubricant, demulsification behaviour of the lubricant/coolant, oil groove design and geometry and the material of the sliding members involved. It is also proposed to investigate some of the tribological issues by replacing the liquid with a solid lubricant such as Molybdenum di-sulphide or Boron Nitride or Graphite impregnated into a polymer. The other aspects of study include possible oil and wear particle analysis.

Additive Manufacturing (AM)

CIIRC® has 3D printing lab facility for prototyping products to be used by various industries for different applications. AM at Centre offers the advantages of mid-sized, thematically focused, scientific groupings within the larger, more diverse academic environment in additive manufacturing.

3D Printing

3D printing is the process of manufacturing physical objects/prototypes of designed geometry directly from their CAD models without any human intervention and without the use of any tools, dies or fixtures. As the object is built in a layer by layer manner in this process, 3D printing is known more appropriately as the Layered Manufacturing (LM) process or rapid prototyping. 3D printing, utilizing the extrusion of thermoplastic material, is easily the most common and recognizable 3DP process. The most popular name for the process is Fused Deposition modeling (FDM). The process works by melting plastic filament that is deposited, via a heated extruder, a layer at a time, onto a build platform according to the 3D data supplied to the printer. Each layer hardens as it is deposited and bonds to the previous layer. The most common material for FDM 3D printers is ABS.

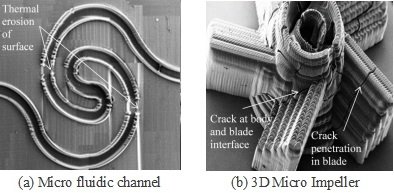

Researchers at the lab have also worked with other 3D printing methods in developing micro products for mechanical and other applications. Figure shows some of the prototypes developed at the Centre using micro stereolithography.

Plating of RP Components

Other topic of interest is plating of rapid prototyped components, optimization of build features, metal coating (Ni & Ag), which provides structural integrity and enhancement in strength and evaluating thermo-mechanical properties. The primary objective includes identification of potential applications in aerospace, medical devices and automobiles.

Plating Methodology of Rapid Prototyped Components

Rapid Prototyped Components Coated with Ag and AU for Space Applications

- Effect of Flow Field Geometry on Hydrodynamics of Flow in Redox Flow Battery. M Narendra Kumar, G C Vijayakumar, K Venkatesh, H B Muralidhara, et al, Energy Engineering, 119 (1), pp 201 – 217, 2022, IF-0.56

- Experimental Investigation of HSFP using MWCNT based Nanofluids for High Power Light Emitting Diodes. Gopalakrishna K, Kathyayini N, G C Vijayakumar, et al. Journal of Mechanical Engineering and Sciences, 12 (3), 3852 – 3865. 2018, IF: 1.49

- Effects of Rayleigh Number with Rotation on Natural Convection in Differentially Heated Rotating Enclosure along Axis Normal to Gravity. Narendra Kumar M., Pundarika G., Rama Narasimha K., Seetharamu K. N. Journal of Applied Fluid Mechanics (2017)10(4): 1125 – 1138, IF: 1.5

- Optimization of Hole Characteristics During Pulse Nd: YAG Laser Drilling of Commercially Pure Titanium Alloy. MuralidharAvvari, Manjaiah M., Mashamba Able, Rudolph F. Laubscher, Raghavendra K. Lasers in Manufacturing and Materials Processing (2017) 4:76-91, IF: 1.67

- A study on chemical and lubrication properties of unrefined, refined and virgin coconut oil samples. Jagadeesh K. Mannekote, Satish V. Kailas, Krishna Venkatesh, KathyayiniNagaraju. Journal of Scientific and Industrial Research (2017)76:100- 104, IF: 0.5

- Tribometer

- High Temperature Stir Casting Furnace

- Thermal Imaging Camera

- 3D Printer

- Multiloop Pulsating Heat Pipe setup

- 8 Channel Data Acquisition Setup

- Viscometer (0.01 to 6 * 106 mPas )

- Magnetic Starrier

- UV bath Sonicator

- Thermal Imager

- Weigh balance (4 digit Accuracy – 0.1mg)

- pH & ORP meter

Thermal management of space electronics using multi turn pulsating heat pipes (PHP). ISRO

Development and fabrication of RP products for the health care consumer and sporting segments-DIC

Effect of Rotation on Differentially Heated Rotating Cavity- SSPS

Design and development of heat sink with fluid pockets for LED Lighting load- SSPS

Influence of oil groove geometry on frictional properties of slide ways

Design and Development of a Novel 3D Printed Splints and Arm Supports for Arm Injured Patients- SSPS

Design and Analysis of Shaft Drive for Two Wheelers- SSPS

Development of Low Cost 3D Printers- SSPS

Multi-turn Pulsating Heat Pipe-SSPS

Performance Evaluation of Vegetable Oil Based Metal Working Fluids-SSPS

Heat Transfer Performance Studies on Heat Sink with Fins used for Electronic Cooling Applications- SSPS

Gopalakrishna K

Gopalakrishna K holds a Master’s in mechanical engineering, having specialized in production engineering from the University of Mysore, and a Ph.D in polymer tribology from NAL-VTU. He has an experience of more than 30 years in academics and research. In addition to tribology, his research and teaching interests include pneumatics and hydraulics, thermal engineering and engineering drawing. He is certified by industry major FESTO in the domain of mechatronics and executed projects that have resulted in five patent filings. With significant research publications in reputed Scopus / Thomson Reuter indexed journals and a monograph to his credit, he has been active in developing autonomous systems for surveillance funded by Naval Research Board-DRDO, coating systems for RP Components by ISRO-DOS, and others. He was a consultant for Avni Energy and developed numerous products. He has supervised students for their doctoral work and is reviewer for journal publications of Elsevier, Sage and Emerald. He is a fellow of professional bodies such as IEI, ISTE, ISAMPE, and TSI. His hobbies include singing and table tennis. Gopalakrishna is a professor at the Centre.

Email Id: gk@ciirc.jyothyit.ac.in

Mohan C B

Mohan C B has a Ph.D. in lubricant tribology from NAL-VTU, Master’s in manufacturing and Bachelor’s in mechanical engineering. He has 28 years of academic and research experience. His areas of interest include coolant tribology, development of additives, optimization of oil groove geometry, materials and manufacturing for use in autonomous and energy systems. He has several research publications in international journals and conferences to his credit. He is a life member of ISTE and TSI, Fellow of Institution of Engineers (FIE) and IIPE. Subjects that interest him are control engineering, theory of elasticity, theory of machines, metrology and measurements, non-conventional energy systems, and friction and wear of metals. He has guided many projects at post graduate and graduate levels. Mohan has been a consultant for the companies M/s Magnum Engineers Pvt.Ltd., Bengaluru, and M/s APRO Lubes Ltd. At M/s Magnum Engineers Pvt.Ltd., he was involved in the design and development of linear reciprocating tribometer for lubricants and coolants characterization. He was involved in the development of new additives for lubricants for slide way applications at M/s APRO Lubes Ltd. He was the coordinator for the student team, from Jain University, that participated in the SAE Aero competitions held at USA. Mohan is also a technical advisor to NDRF-IEI and worked on the development of a VTOL system funded by DRDO being the PI. Apart from academics and research activities, he also participated in extracurricular activities. His hobbies are music and reading books on philosophy. Mohan is currently a professor at the Centre.

Email Id: mohan.cb@ciirc.jyothyit.ac.in

G C Vijayakumar

G C Vijayakumar, professor at CIIRC, holds Ph.D. in mechanical engineering from VTU together with an MBA in financial management from Southeastern University, USA, and M.E. in machine design from Bangalore University. He has a combined experience of 38 years in academia, research, and industry in India and abroad. His experience spans academics/training management and administration, undergraduate (B.Tech.) and graduate (M.Tech., MBA) teaching, training need analysis, life skills and behavioral skills training, content design/development and delivery, faculty/trainer recruitment/selection and appraisal, vendor management, feedback design and implementation, faculty/management development programs, and strategic learning initiatives. While in the industry, he has held senior positions such as Vice President and Head – Training in an US$2billion, SEI CMM Level 5 organization in Muscat, Sultanate of Oman; Vice President – Projects and Processes and Vice President – Strategy and Programs in an organization within the international education and training space; Country Head – Training in an engineering design software distribution and implementation company; and, Training Manager in VIT University. He has a great flair for both teaching/training and active research; students receive him very well. His teaching interests include fluid mechanics, hydraulic machinery, design of machine elements, strength of materials, applied thermodynamics, I C engines, financial management, securities and portfolio management, and other management courses. His primary areas of research include analysis and prediction of business failure, general management, tribology, and thermal engineering. He has published several papers in both mechanical engineering and financial management in national and internal journals.

He has trained at organizations/institutions such as Bahwan CyberTek LLC, Muscat; CMR Institute of Technology; Centre for American Education Pvt. Ltd.; Dell Computers; Trent Ltd. (A Tata Enterprise); The Oxford College of Engg.; Prabhavati Builders and Developers Pvt. Ltd.; PES Inst. of Tech. and Mgmt., Shivamogga; RV College of Engg.; Unisys Ltd.; and VIT University, Vellore.

An indicative list of his training programs he has conducted include Assertivenessand Aggressiveness, Business Communication, Business Etiquette, Emotional Intelligence, Communication & Presentation Skills, Email and Telephone Etiquette, Emotional Intelligence, Leadership Skills (Managing to Leading), Conducting Effective Meetings, Conflict Management & Resolution, Creative Problem Solving, Effective Delegation, Effective Interviewing and GD skills, Managing and Leading Change Successfully, Strategic Decision Making, Team Building and Team Management Skills, Unwind to Rewind (Stress Management).

Vijayakumar is life member of ISTE and CSI, and a member of IIPE, ISTD and AIMA. His other interests are Sudoku, Kakuro, predictive astrology, horary astrology, and the stock market.

Email Id: vijay.gc@ciirc.jyothyit.ac.in

M Narendra Kumar

M. Narendra kumar is a Professor at CIIRC. He holds a bachelor’s degree in Mechanical Engineering from Bangalore University, a GATE scholar with Master’s in Energy Technology from Pondicherry University and a Ph.D in Heat Transfer & CFD from V.T.U. He has a combined experience of 18 years in academia, research, and industry. His research and teaching interests includes Heat Transfer, Thermodynamics, Computational Fluid Dynamics, Fluid Dynamics, Refrigeration & Air Conditioning, Turbo Machines and I C Engines. He has quite a few research publications to his credit and has participated in several workshops He is also a member of a few professional bodies

Email Id: narendra.kr@ciirc.jyothyit.ac.in

Raghavendra Krishna

Dr Raghavendra Krishna is a 3D Printing (3DP) research facilitator at CIIRC. His 3DP research focuses on novel design and development of products for multiple applications ranging from Art to Architecture and Engineering to Medical. Dr RK is an Associate Professor of Additive Manufacturing and Rapid prototyping in the Department of Mechanical Engineering where he teaches Post Graduate and Undergraduate students. He has published multiple Books and Book Chapters in the domain of Additive manufacturing with special emphasis on 3D Printing. Previously, he has worked as a researcher at NITK and CMTI. He was involved in design and development of Microstereolithography to develop micro scale components for use in medical applications. His development work has been published in various peer-reviewed Conferences, Journals and Books.

He has a P.hD. in Additive Manufacturing with Master’s in Manufacturing Technology from NITK Surathkal and Bachelors in Mechanical Engineering from VTU Belgaum. Continuing his research at CIIRC – JIT in 3D printing, He is also a promoter of Indian manufacturing domains through www.mfggateway.com, GoKhaadi and also works with Indian naturopathy medicine practioners in his spare time through Naivaidhya.

Email Id: raghavendra.r@ciirc.jyothyit.ac.in